My Portfolio

Remote Control of Water Treatment Station Using Siemens S7-1200 PLC

This project focused on remotely controlling a water treatment station by integrating the Siemens S7-1200 PLC with an OPC server and multiple client connections. The system was designed to operate in both automatic and manual modes, ensuring high reliability in industrial automation. The primary objectives included establishing a remote control setup, integrating the PLC with the OPC server, and deploying two UA Expert clients for testing, alongside a Python-based client for enhanced control. Key features included automatic and manual operation modes, with remote execution capabilities through UA Expert and Python clients. Technologies used included the Siemens S7-1200 PLC for reliable process control, OPC server for communication, UA Expert for system validation, and Python for advanced remote management. The project successfully demonstrated robust control over the water treatment process.

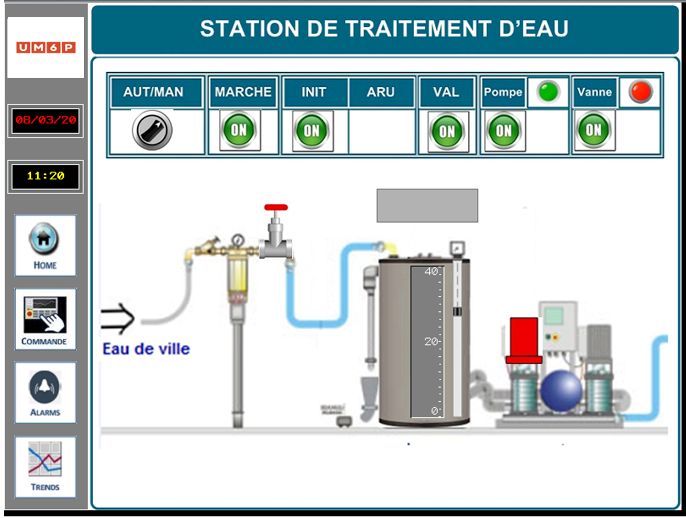

Advanced HMI Interface Development for Water Treatment Process Using Vijeo Designer and Unity Pro

I created an advanced HMI interface for a water treatment process, leveraging Vijeo Designer for interface development and Unity Pro for PLC programming. The project focused on improving user interaction and control over operations by incorporating a highly intuitive interface with real-time data monitoring and comprehensive control capabilities. Key accomplishments included designing a user-friendly interface, enabling effective real-time process visualization, and seamlessly integrating with Unity Pro to ensure reliable and efficient system performance. This experience enhanced my skills in HMI design and industrial process control, showcasing my ability to integrate diverse technologies for optimal performance.

Supervision and Data Acquisition of a Simulated Industrial Process Using Ignition Edge

In this project, I developed a supervision and data acquisition system for a simulated industrial process using Ignition Edge. The process involved managing a reactor and a storage tank, controlling valves, pumps, and monitoring key variables such as levels and temperatures in real time. I created a synoptic interface to visualize analog variables (reactor level, storage level, and temperature) and discrete variables (valve states and operating modes). I implemented trend curves for the reactor temperature and tank levels and configured alarms for critical thresholds (storage exceeding 4000L and temperature exceeding 60°C). Additionally, I provided a solution to log process data with a 1-second sampling rate into a CSV file and transfer it to a MySQL database. This project allowed me to develop skills in SCADA systems, real-time monitoring, Python scripting, alarm management, Modbus communication, and historical data storage.

Design and Implementation of a Network Architecture for Automated Guided Vehicles Using Modbus and TCP/IP

I developed a network architecture for Automated Guided Vehicle (AGV) robots, utilizing Modbus and TCP/IP protocols. The project involved implementing a robust client-server communication system, enabling remote operation of the AGV through a TCP/IP interface and sending commands via RS232 Modbus. This setup ensured precise and efficient control for automated material handling. The experience significantly deepened my knowledge in industrial automation, network communications, and robotic control systems.

CAD Project - Solar Vehicle Design

Our team embarked on an exciting Computer-Aided Design (CAD) project to create a digital model of a solar vehicle. This initiative combined theoretical knowledge with practical application, enhancing our skills in 3D modeling, mechanical assembly, and collaborative project management. Using SolidWorks, we successfully modeled precise components, coordinated their assembly, and generated detailed technical drawings. This project not only reinforced our mechanical design expertise but also prepared us for real-world industry challenges by honing our teamwork and technical skills.

Workflow Optimization for Bundle Product Packaging at P&G

At P&G, I worked on a workflow optimization project aimed at reducing labor and packing staff effort for bundle product packaging. By reorganizing the "poste de travail" (workstation) layout and integrating conveyors into the process, we were able to streamline operations and improve efficiency. This organizational improvement resulted in significant time savings and reduced manual handling, cutting operational costs by an equivalent of 150,000 DH annually. The project not only enhanced productivity but also contributed to a more ergonomic and efficient work environment for the team.

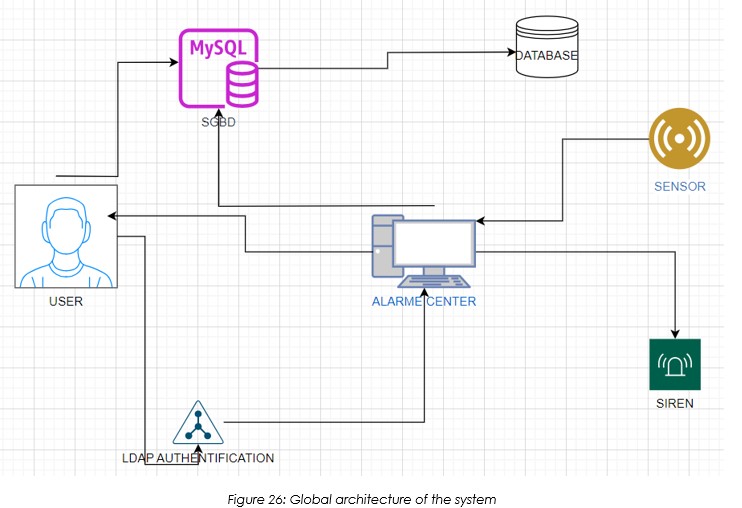

System Engineering Project - Anti-Intrusion Alarm System

Our system engineering project focused on designing an anti-intrusion alarm system. This system utilizes a combination of sensors, alarms, and communication technology to detect unauthorized access and alert the user in real-time. The project aimed to enhance security measures by developing a responsive and reliable system capable of immediate threat detection and response. This project not only strengthened our expertise in system engineering and sensor integration but also equipped us with practical skills in creating efficient and user-friendly security solutions.

Simulation-Based Optimization of a Complex Production Process Using ARENA

I worked on a simulation project to optimize a production process where products pass through multiple machines, each operating at a different rate. Using ARENA Simulation, I built a detailed model of the production line to analyze performance and identify bottlenecks. By experimenting with resource allocation and adjusting machine priorities, I was able to explore different scenarios and evaluate their impact. Using the software’s visualization features, I presented the results in an easy-to-understand way, illustrating how the proposed optimizations could improve efficiency. Although the project was a simulation, it provided valuable insights into enhancing workflow and resource management in a real production environment.

YTCA Robotics Competition - UM6P

As part of the inaugural YTCA Robotics Competition at UM6P, I had the opportunity to collaborate with CAYSTI, the UM6P GTI department, and the 1337 Coding School team. My role involved guiding participants in basic robotics, electronics, and IoT as they developed innovative solutions to address agricultural challenges in Africa. This international event fostered collaboration across borders, and it was inspiring to see the participants apply their knowledge to solve real-world problems. This experience reinforced the importance of teamwork and technology in driving impactful change.

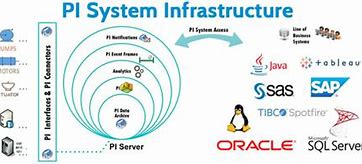

Implementation of Condition-Based Maintenance with AVEVA OSIsoft PI System

This project focused on establishing a comprehensive status and condition report for condition-based maintenance practices. I proposed and implemented monitoring solutions for the new deployment of the AVEVA OSIsoft PI System, enhancing predictive maintenance capabilities. Key contributions included configuring alarms and notifications within the PI System to monitor excessive vibration and temperature, improving response times to potential equipment issues. Additionally, I enhanced the intuitiveness of the PI Vision interface for more user-friendly data visualization and developed a structured equipment hierarchy across multiple plant units to streamline data organization on the platform.

Smart House System

Developed a remote-controlled smart home integration system utilizing a cloud server. The system is built with Arduino Mega, ESP32, and various sensors (such as temperature, humidity, and motion sensors) along with actuators (including servo motors and relays). A mobile application, created via RemoteXY.com, enables global remote control, ensuring efficient management of home automation features.

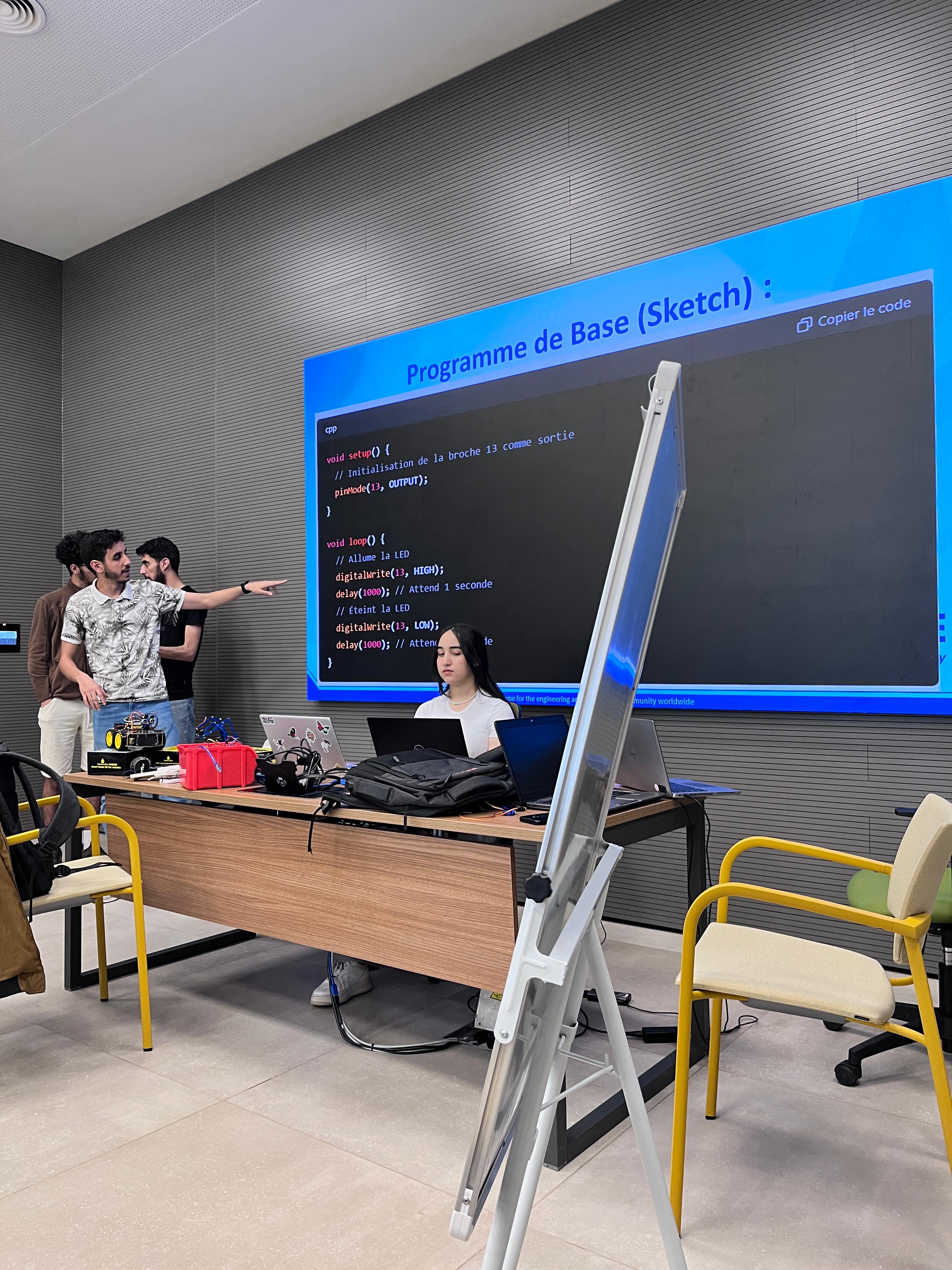

C++ Object-oriented programming Training with Arduino for robotics at Cyborgs Club

I conducted a hands-on training session in Object-Oriented Programming (OOP) with C++ using Arduino, specifically tailored for students of Lycée Mohammed VI d'Excellence. This training focused on applying OOP principles to control robotic systems with Arduino, providing students with both a theoretical foundation and practical skills. Through this experience, participants developed coding proficiency and hands-on knowledge in robotics, fueling their interest and creativity in the field. The students’ enthusiasm and dedication made this training especially rewarding, and I am excited to see the innovations they’ll pursue in robotics.

Insightful Visit to Managem’s Tizert Site: Advancements in Metals Mining and Digitalization

I visited Managem’s Tizert site on 20th May, we had the privilege of visiting Groupe Managem's latest monumental project in Morocco – the Tizert site. This visit was a deep dive into the core values and principles that drive Managem’s success and its progressive approach to the mining industry. During our discussions, we went through Managem's commitment to sustainability, innovation, and excellence. We explored how the company thrives in the technology era, leveraging digitalization to enhance operational efficiency and address industry constraints. It was inspiring to see the tangible results of their digital transformation initiatives firsthand.

Leadership in Robotics Innovation: Building a Self-Managed Team and Driving Agile Project Success at Cyborgs Club

As the president of the Cyborgs Club, I led our efforts to onboard new board members, marking an exciting new phase for our expanded leadership team of 12. In collaboration with Student Organizations, Leadership, and Engagement (SOLE) at UM6P, I focused on fostering a self-managed team by implementing the Scrum Agile methodology through Jira. This approach empowered us to tackle robotics projects efficiently, while also organizing robotics trainings and competitions within UM6P. With this dynamic, agile framework, our team is well-equipped to drive innovation and make significant strides in our robotics and technology initiatives.

Enriching Visit to OCP Youssoufia - Phosphate Valorization and Digitalization

I had the opportunity to visit the OCP site in Youssoufia, where I gained valuable insights into the phosphate valorization process, from extraction to the production of fertilizers. The visit also focused on exploring process optimization and digitalization initiatives aimed at enhancing operational efficiency and competitiveness. The integration of advanced technologies promises to improve product quality, reduce costs, and minimize environmental impact. It was an inspiring experience, and I appreciate the warm welcome and transparency of the OCP Youssoufia team, whose commitment to innovation is remarkable.